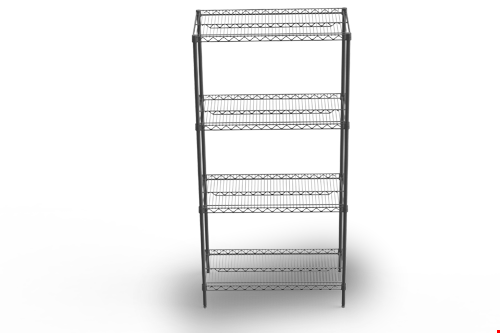

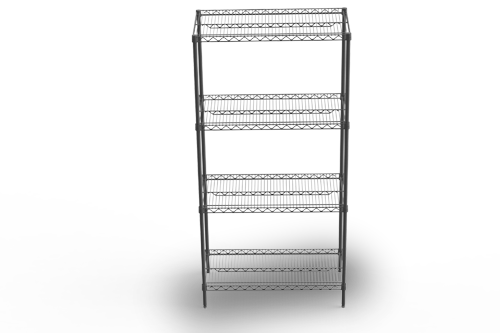

Product Detail

53-B- Wire stacking rack /POWDER Storage Shelves

Wire racks are manufactured from powder coated plate sheet. The rack body consists Ø 5.8 mm thick rods on the sides and the middle and Ø 3.5 mm thick rods at the top with 20 mm intervals Ø 5.8 mm frame rods on the sides and Ø 4.5 mm wire parts with mesh pattern are mounted to increase durability. On each corner of the racks, cone parts manufactured from 2mm thick and Ø 32 mm diameter pipes are welded. To strengthen the tall and wide racks’ thick rods in the middle section, additional parts made of mesh and Ø 5.8 rods are mounted. The racks are treated with electro polishing and its surface is strengthened against corrosion. Rack unit console is manufactured with powder coated at 25 mm intervals on a Ø 25 mm diameter pipe. The console has the same surface treatment of the racks. After the electro polishing treatment, toothed zamak parts are mounted on the lower section of the console and bolts are mounted for height adjustment. Black plastic plugs are mounted on the bolts and the upper sections of the console. Mounting the racks on the console is done by mounting the special formatted polyamide parts on the desired numbered grooves and mounting the racks on the cone parts at the corners.

Wire racks are manufactured from powder coated plate sheet.

The rack body consists Ø 5.8 mm thick rods on the sides and the middle and Ø 3.5 mm thick rods at the top with 20 mm intervals

Ø 5.8 mm frame rods on the sides and Ø 4.5 mm wire parts with mesh pattern are mounted to increase durability.

On each corner of the racks, cone parts manufactured from 2mm thick and Ø 32 mm diameter pipes are welded.

To strengthen the tall and wide racks’ thick rods in the middle section, additional parts made of mesh and Ø 5.8 rods are mounted.

The racks are treated with electro polishing and its surface is strengthened against corrosion.

Rack unit console is manufactured with powder coated at 25 mm intervals on a Ø 25 mm diameter pipe.

The console has the same surface treatment of the racks.

After the electro polishing treatment, toothed zamak parts are mounted on the lower section of the console and bolts are mounted for height adjustment.

Black plastic plugs are mounted on the bolts and the upper sections of the console.

Mounting the racks on the console is done by mounting the special formatted polyamide parts on the desired numbered grooves and mounting the racks on the cone parts at the corners.